Your company’s packaging is important. Any package received by your customers is a moving advertisement for your brand and corporate identity. Deciding on what type of packaging to invest in will ultimately be determined by your budget.

Why use custom shipping tape?

- Cost Savings – Custom tape is less expensive when compared to printed boxes.

- Space Considerations – Custom tape can be ordered in small quantities and take up less space to store. Custom boxes require large minimum purchases and use up large areas of storage space in warehouses.

- Serves multiple purposes – Custom tape seals your packages, improves security and advertises and markets your brand all at once. Boxes can’t do all of that!

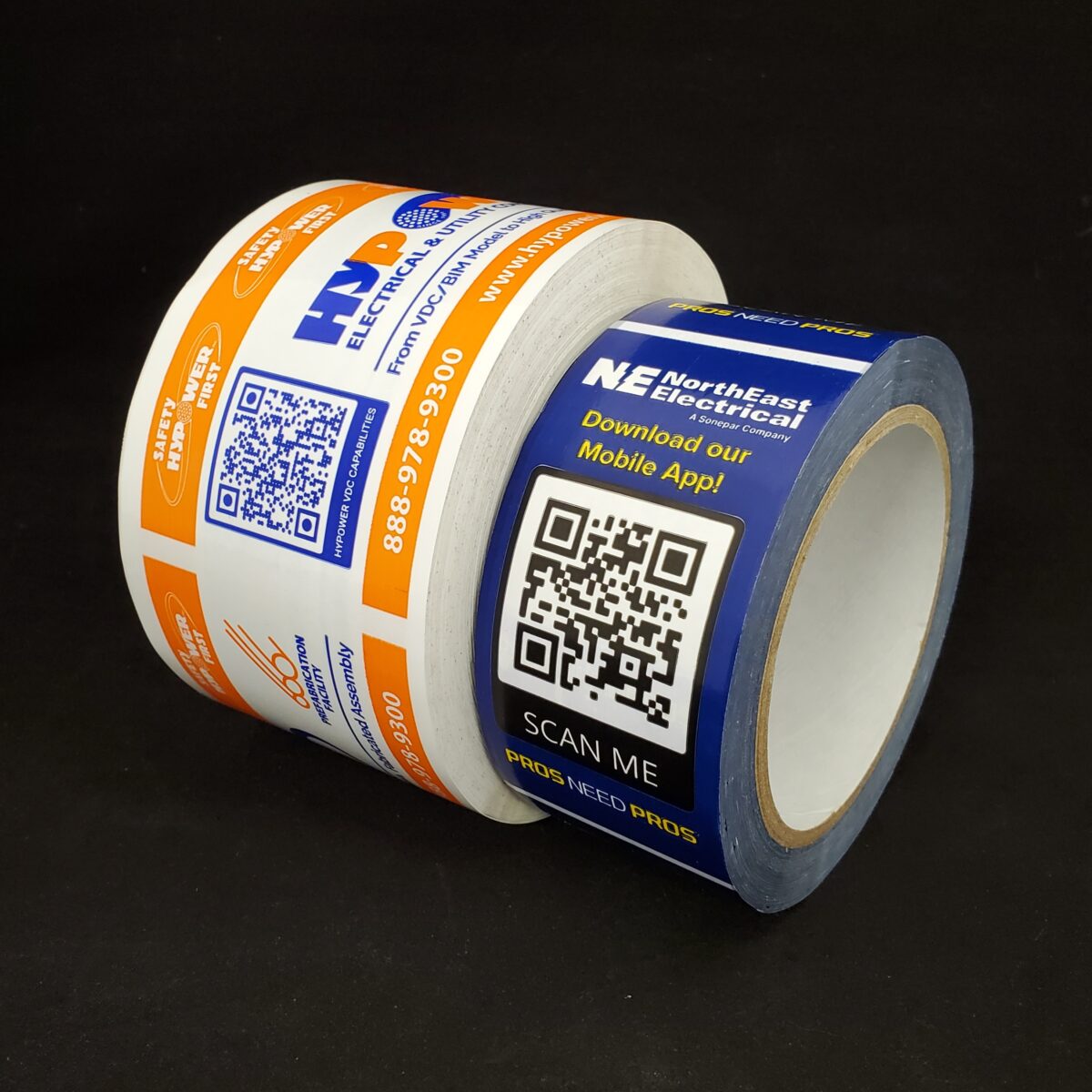

- Versatility – What you choose to print on your custom tape can include logos and company names, contact information, QR codes or special handling instructions. And if you want to change the look of the tape it is so easy to have a new tape design created.

- Security – Using a custom shipping tape makes it more obvious that a box has been tampered with, reducing the odds that something will happen to your shipments.

What to consider when ordering custom packing tape?

- Type of tape and strength needed – Consider what you are shipping and the weight of your shipments.

- Length – We offer hand-held rolls that fit on a hand-held dispenser or 1000 yard machine rolls for industrial settings.

- Width – How wide you want your tape to be can be influenced by the weight of the shipments and the grip strength you want in your tape.

- Tape Color – Custom shipping tape catches the eye so much more than plain tape. We offer a range of colors depending on the type of tape you need.

- Number of Inks – We offer 11 standard colors plus the ability to print custom PMS colors. Having this range of color helps bring your custom packing tape to life.

A well-designed custom shipping tape enhances a company’s image and boosts your customer’s opinion of your company. Figuring out the best options for your shipments helps you to get the most out of your tape, making a wise choice if you have a smaller advertising and marketing budget. We’ve been doing this since 1985. Contact us if you are interested in using custom printed tape or would like more information.

1-800-992-1522

1-800-992-1522  My Account

My Account

Register / Login

Register / Login